Products

Samyoung M-Tek, Leader of the industrial materials manufacturing!

Expansion Joint

Explanation

에너지흡수 성능이 우수한 저항복점 강재를 심재로 사용하여 강재의 탄/소성에 의한 지진에너지 소산과, 심재가 압축시에 좌굴하는 것을 구속하기 위해 ㄷ형 채널강재로 보강한 강재형 제진장치

-

SYFR

- Type : Complex finger rail structure

- Connection & load transmission: Understructure consists of studded anchors that connect to skewed iron bars in slabs for load dispersion.

- Durability & safety: The upper sides of the fittings have a wider contacting surface with wheels, decreasing the shock to 1/10 that of the rail joints for better durability and safety.

- Waterproofing: A rubber seal is inserted in rail grooves for better waterproofing quality.

- Mobility: Wheels make constant contact with the rail surface, and makes less noise and shock.

- Unit length of product

- Upper fingers: 1~2m, in shape of fingers

- Lower fingers: In the shape of rails, with the same length as the width of the road

- Maintenance/repair: Upper finger plates are replaceable for easy maintenance and repairs

-

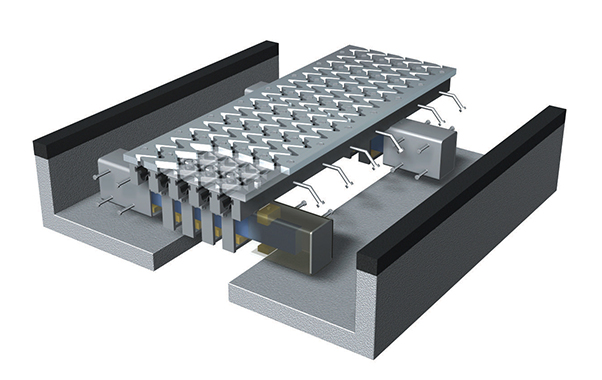

SYCF

- Type : The upper part consists of middle fingers, along with edge fingers on either sides; and the lower part is a complex structure with one middle rail and a hollow box.

- Connection & load transmission: The upper part has edge fingers that are connected with edge rails of the lower part by high strength bolts; hollow boxes and anchor hoops are connected to iron bars in the slabs for load dispersion.

- Durability & safety: Upper edge fingers have wider contact area with wheels for stress dispersion, guaranteeing high durability and safety.

- Waterproofing: The rubber seal is compressed between fingers and rails connected by bolts.

- Mobility: Fingers of the upper parts prevent wheels from treading and making noises

- Unit length of product

- Upper edge fingers: 1~2m, finger shaped.

- Lower rail: Same length as the width of the road

- Maintenance/repair: Upper edge fingers are replaceable for easy repair

-

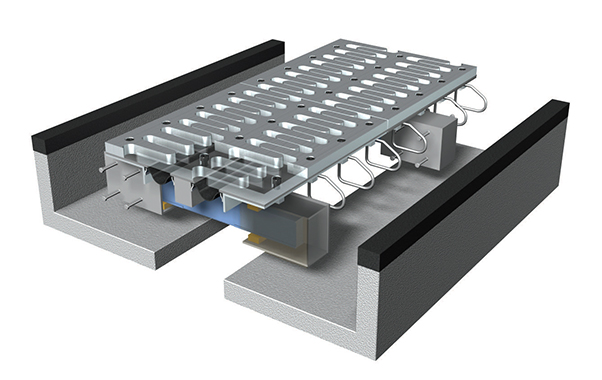

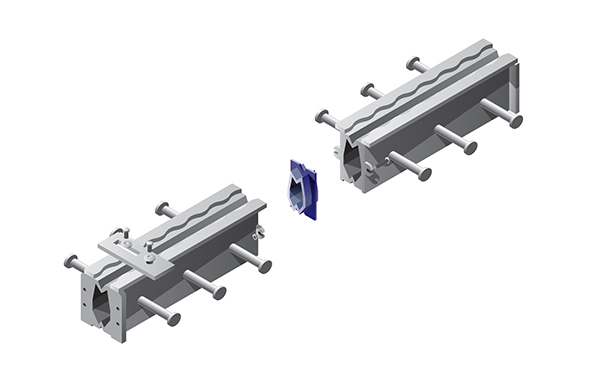

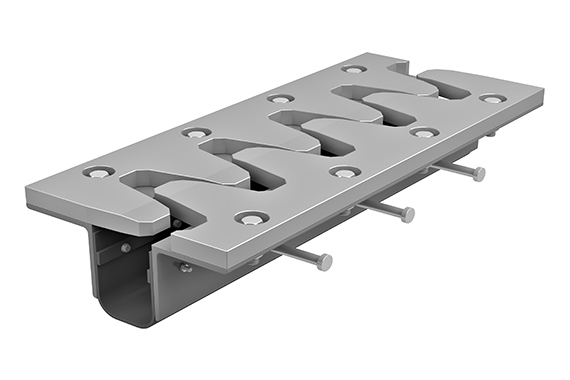

SYIF

- Type : Two finger-shaped metal bodies are connected to the lower rails by high strength bolts and studded anchors; the length of fingers changes with regular intervals

- Connection & load transmission: The lower structure of the joint is connected to iron bars in the bridge slabs by angles and studded anchors for stress dispersion

- Durability & safety: Fingers disperses stress from contacting surface of wheels; wave pattern in post-placing concrete enhances adhesion and prevents damages.

- Waterproofing: The rubber seal consists of compressed fingers and rails connected with bolts, featuring superior waterproofing capacity

- Mobility: SYIF makes less noise and provides superior mobility for vehicles

- Unit length of product: Length of lower structure of expansion joint is same as the width of the bridge; upper fingers are 1~2m long.

- Maintenance/repair: Upper edge fingers are replaceable for easy repair.

-

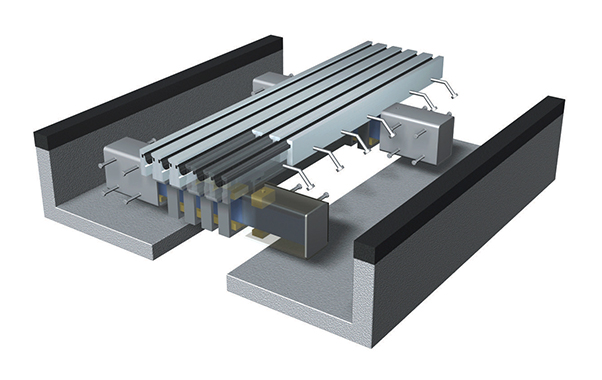

SYR

- Type : Steel rail and support bars

- Connection & load transmission: Wing hooped lower structure is connected to iron bars in the slab for load transmission.

- Durability & safety: SYR is made of steel for superior safety

- Waterproofing: Rubber seal in the rail grooves for superior waterproofing

- Mobility: Makes louder noise and greater shock in greater expansion movement (No. 100 and higher)

- Unit length of product: Product length is the same as the road width, in transportable shape

- Maintenance/repair: Full replacement after breaking the concrete layer

-

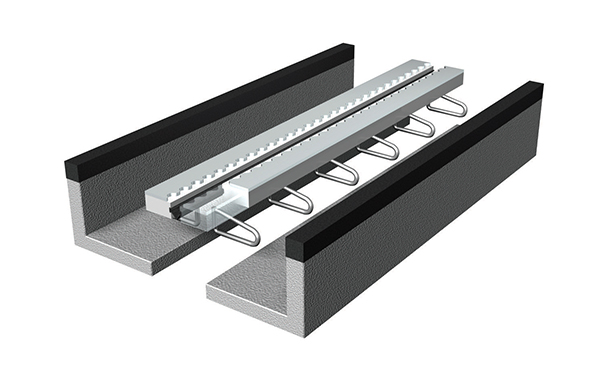

SYCRMJ

- Durability: Superior and semi-permanent durability due to steel upper part

- Mobility: Driving surface is in round shape for less noise and superior mobility of vehicles; highly durable against shock by wheels and abrasion.

- Constructability: Bolt type pre-setting devices are easily adjustable on-site according to temperature or the general condition of the premises

- Maintenance and repair: Simple structure for easy construction; the SY-CRMJ is manufactured in 1.8m-long segments for rapid installation and economic maintenance & repair

- Waterproofing: Special reinforcement between the segmented products for superior waterproofing

- Sound absorption: Sound absorbing material in the SY-CRMJ dampens vibration and shock to the expansion joint caused by vehicle wheels, dampening noise and shock to the entire cross-section of the bridge

-

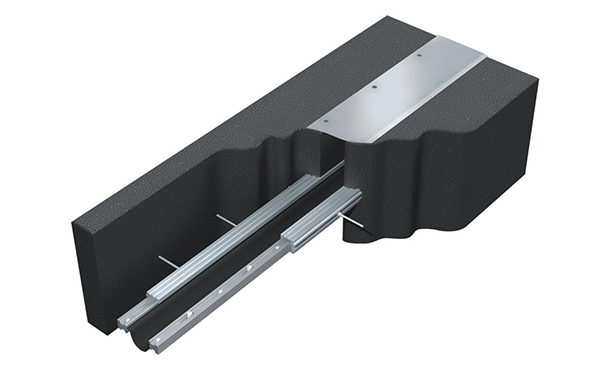

SYCRFJ

- Durability: Processed H-BEAM for semi-permanent lifecycle against shock and abrasion

- Mobility: Minimal discontinuity for better smoothness and mobility. Bolt-type pre-setting devices are easily adjustable on-site according to the temperature or the general condition of the premises

- Maintenance and repair: Simple structure for easy construction; the SY-CRMJ is manufactured in 1.9m-long segments for rapid installation and economical maintenance & repair

- Waterproofing: Special reinforcement between the segmented products for superior waterproofing

- Sound absorption: Sound absorbing material in the SY-CRFJ dampens vibration and shock to the expansion joints caused by vehicle wheels, dampening noise and shock to the entire cross-section of the bridge

- Blocking of contaminants: The filling-material blocks out the introduction of large contaminants to gaps of the rail, preventing the loss of expansion movement.

-

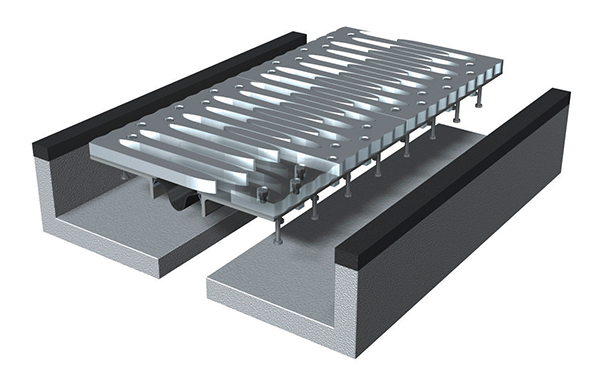

SYSTM

- Overview: Improved version of the existing mono-cell and new mono-cell joints; upper surface of the rail joints are processed in the shape of mono-cells; All-in-one type, or custom-made type products (unit length: 1m) available for order; applicable to partial repairs.

- Durability: Semi-permanent durability thanks to the same material as the rails

- Mobility: Mono-cell patterns in the upper slabs guarantee superior vehicle mobility

- Applicability: Same structure as rails: transverse and longitudinal installation possible; applicable to many types of bridges, including skewed bridges and curved bridges

- Waterproofing: The rubber seal is assembled with the existing rail for perfect waterproofing; apron attached to the kerb.

-

SYREAL

- Slide balls to the fixed rail grooves for easy replacement of waterproof seals

- Semi-permanent fixed rail

- Longitudinal & transverse sections of slabs embraced

- Fixed rails are embedded before depositing concrete; strict management of premises needed

- Teeth on the outside of the fixed rail fix concrete.

-

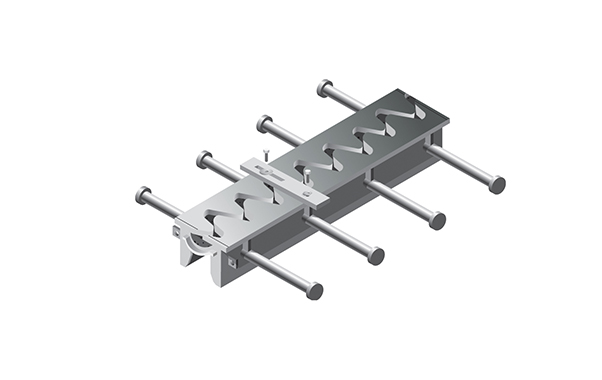

MAS

- Type: A two-finger metal body is installed with a lower rail, high-strength bolts, and stud anchors. Finger lengths are differentially applied at regular intervals.

- Assembly and load transfer: The substructure of the expansion joint is connected to the reinforcing bars of the bridge deck using angle and stud anchors to distribute the load.

- Durability and usability: The contact surface of the wheel is distributed across the fingers, providing excellent durability and stability. Applying the wave pattern shape to the concrete improves adhesion and prevents damage to the concrete.

- Waterproofing: Excellent waterproofing as the fingers and rails are fixed, compressing the rubber seal with bolts.

- Driving performance: Low noise and excellent driving performance.

- Unit length of the product: The lower structure of the expansion joint is the same length as the bridge width, and the upper finger part is manufactured and